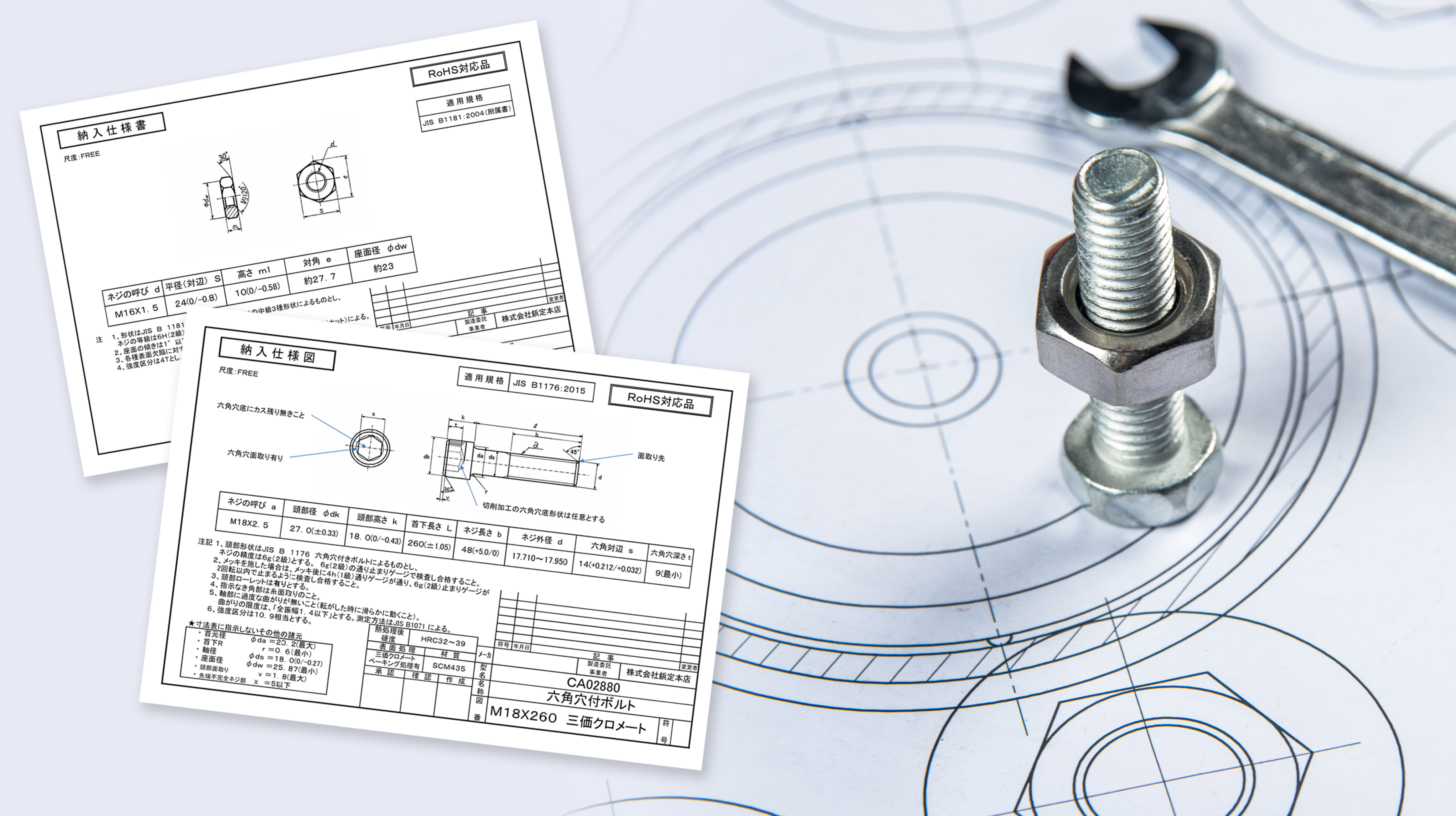

Standard Specification Products(Sample Product)

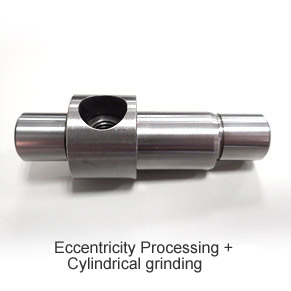

Custom Metal Processing Products(Sample Product)

ThreeBond

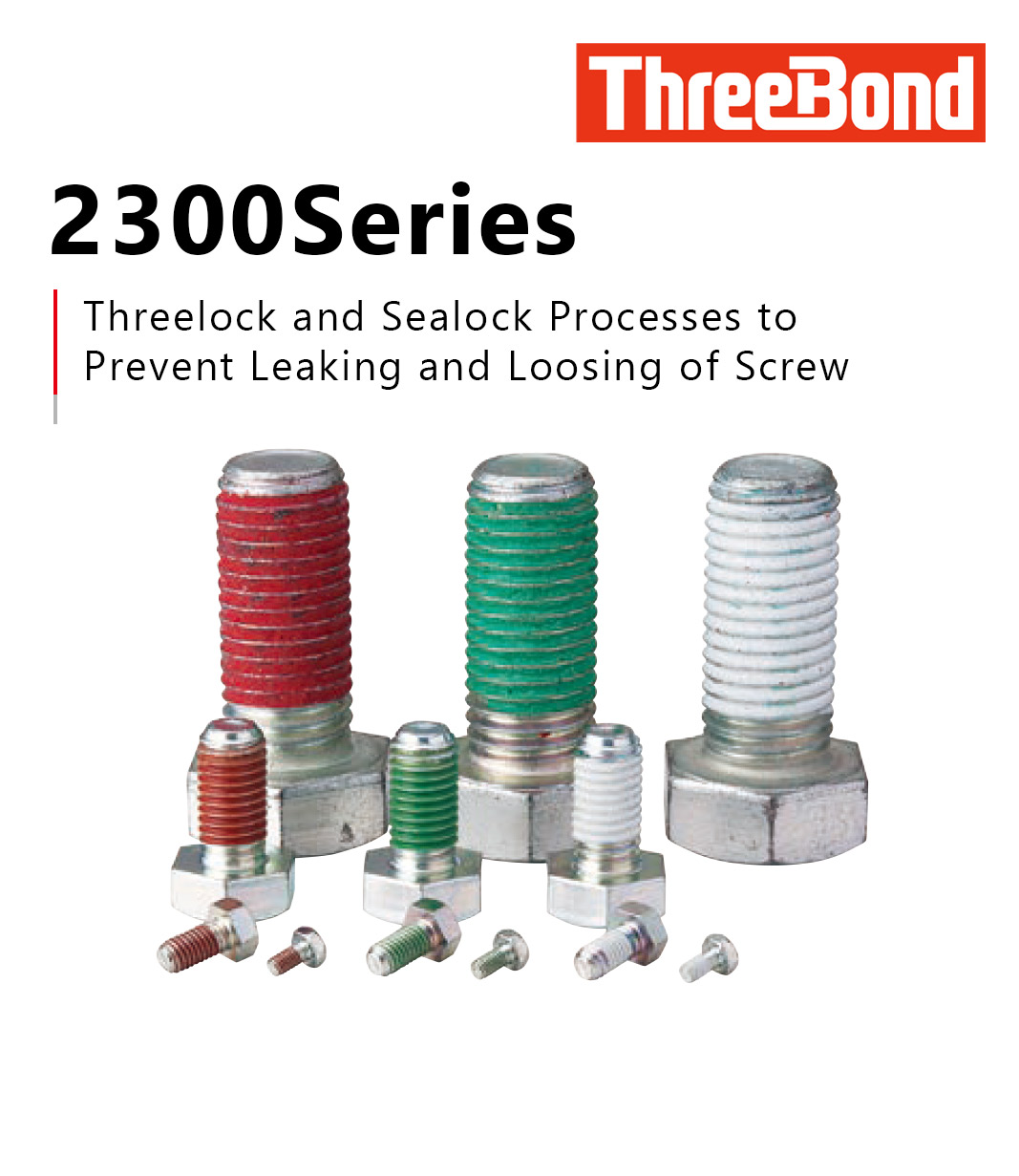

ThreeBond 2300/2400 Series

The ThreeBond 2300/2400 Series features pre-coated fasteners, where sealants or locking agents are applied

in advance to threaded parts such as screws, bolts, and pipes. This gives the fastener built-in sealing or locking functionality, which activates during tightening.

ThreeBond provides several pre-coating solutions: the Precoat Bolt-Mec process uses microencapsulated adhesives that cure upon fastening,

ThreeLock fuses nylon onto threads for a reusable lock, and Sealock adds a sealing agent to prevent leaks.

These technologies streamline assembly, eliminate the need for separate sealants or locking agents, and enhance product reliability.

■ThreeBond 2300 Series Prevention of Thread Loosening and Leakage

●ThreeLock Process

A nylon resin with excellent elasticity, wear resistance, chemical resistance, and weatherability is fused onto the threads.

When tightened, the nylon’s elastic rebound within the thread clearance prevents loosening.

The coating allows for five or more reuses, meeting JIS B 1056 standards, and performs reliably in temperatures from approximately -50°C to 120°C.

●Sealock Process

A special synthetic resin is baked onto the threads. During fastening, it deforms to fill the thread gaps, instantly providing a seal.

The high-temperature version maintains sealing performance under hydraulic pressure up to around 170°C.

ThreeBond 2400 Series Prevention of Thread Seizure and Leakage

●Precoat Bolt-Mec Process

A microencapsulated reactive adhesive is applied to the threads. When tightened, the capsules rupture and the adhesive cures rapidly.

Full strength is reached within 24 to 48 hours, forming a strong, oil-,

chemical-, heat-, and weather-resistant bond. It offers reliable locking up to about 100°C (150°C for high-temp types) and sealing up to around 170°C.

For detailed specifications, please contact our sales department.

Fastening and Industrial Tools

Fastening and Industrial Tools

We offer a wide range of fastening tools, including Phillips and flathead screwdrivers,

hex wrenches, and hex keys. If you need rare sizes not found at hardware stores, please consult us.

We also provide specialized tools such as tamper-resistant Torx drivers, custom manufacturer tools, and riveting tools. Power tool bits are also available.

For details, please contact our sales department.

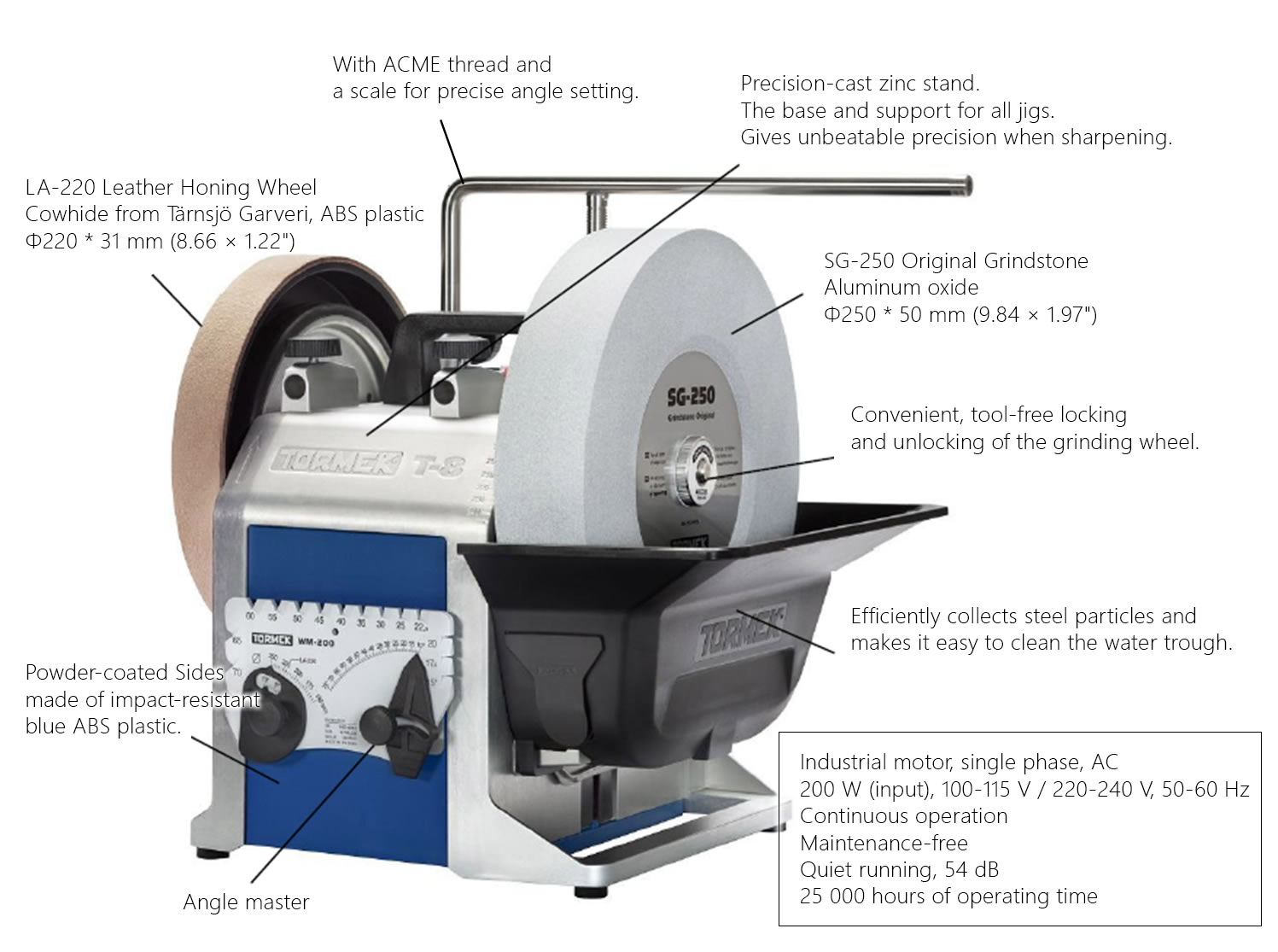

Tormek Water-Cooled Sharpening MachineWe are an authorized distributor of Tormek®, a water-cooled sharpening system developed by Tormek AB in Sweden.

This machine enables efficient and precise sharpening of blades and cutting tools. It is well-suited for professional applications,

including the sharpening of machining tools and restaurant knives. For individual users, it is ideal for maintaining kitchen knives and woodworking tools.

Purchases can be made through our official online store, Byosada Honten Main Shop, your reliable source for fasteners and related products.

Authorized Distributor of Tormek®

【Features】

✔ Sharpens All Types of Blades

A wide range of patented jigs allows for the sharpening of almost any blade. Tormek’s innovative water-cooled system is trusted worldwide.

✔ Accurate and Repeatable Results

The jig angle can be recorded for consistent sharpening, even on curved or complex blades.

✔ Razor-Sharp Finish

The leather honing wheel produces a finely polished, razor-sharp edge suitable for both professional and personal use.

✔ Efficient Resharpening

Once the angle is set, only minimal material removal is needed for future touch-ups, saving time and extending blade life.

✔ Controlled and Safe Operation

Low-speed rotation prevents overheating and excessive wear. The water-cooling system eliminates sparks and airborne dust, ensuring a clean, quiet, and safe process.

✔ Reliable Quality

Tormek offers long-lasting quality and performance—a smart investment for both professionals and hobbyists.

GPH200

Bite Gauge

The bite gauge is used to evaluate the quality of cross recesses in small screws.

The inspection is performed by inserting the gauge vertically into the recess; if it engages securely and does not fall out, the recess passes.

Gauges are available in various sizes depending on the recess dimensions — The image shows the No.2 gauge.

For purchases or inquiries, please contact our Sales Department.

Q Gauge

Q Gauge

The Q Gauge measures the depth of cross recesses in small screws.

If the depth falls outside standard tolerances, issues like cam-out may occur during tightening.

Unlike the bite gauge, which gives a qualitative check, the Q Gauge provides a precise, quantitative measurement.

Available in various sizes depending on the recess; the model shown is No.2.

For inquiries or purchases, please contact our Sales Department.

Plug Gauge

Hexagon Socket Plug Gauge

The Hexagon Socket Plug Gauge is used to inspect the hexagonal holes of socket head bolts and set screws.

Since accurately measuring the flat-to-flat distance with calipers is difficult, this gauge is used to determine pass or fail.

There are specified tolerances for the flat-to-flat distance, and acceptance is judged by whether the gauge passes through or stops at the hole.

The hexagon end on the left side of the photo checks for “go” (fits into the hole), while the square end on the right checks for “no-go” (stops at the hole entrance).

The model shown measures 8mm flat-to-flat.

For purchases or inquiries, please contact our Sales Department.

Thread Gauges

Thread Gauges (Screw Limit Gauges)

According to JIS standards, screws must meet two key criteria:

The outer (or inner) diameter must fall within the specified tolerance range.

The screw must pass inspection using a thread gauge.

Thread gauges verify that the screw is within the upper and lower tolerance limits by using corresponding limit gauges.

For external threads, such as those on small screws or bolts, a ring gauge is typically used:

GO gauge: The screw must fully pass through without resistance.

NOT GO gauge: The screw should stop within two full turns when inserted.

Thread gauges are available for both external and internal threads in a variety of sizes.

The photo shows an M10 × 1.0 external thread ring gauge — the GO gauge on the left, and the NOT GO gauge on the right.

For purchase inquiries, please contact our Sales Department.